Contact Us

E-mail:

sunjiyang@meidexiang.com

Tel/Wechat/WhatsApp:

+8618633701166

Tel/WeChat:

+86-13663271100

Address:

Hope New District, Mengcun, Cangzhou City, Hebei Province, China (East of Lijiapu Bridge, Cangyan Road 283)

Round pipe to square pipe

- Product Description

-

Definition and Scope

Deep processing of steel pipe refers to the process of further improving and expanding its performance, shape or use through various processing techniques on the basis of steel pipe. It involves a wide range, including changes in the physical shape of the steel pipe, surface treatment, connection improvement and other aspects.

Main processing technology

cutting processing

Sawing: Use a metal sawing machine to cut steel pipes. This method can accurately control the length of the steel pipe and is suitable for cutting steel pipes with larger diameter and thicker wall thickness. For example, in the processing of steel pipes for building structures, long steel pipes need to be cut into components of a specific length, and sawing can ensure that the cutting surface is relatively flat and the dimensional accuracy is high.

Flame cutting: Use the high temperature generated by the gas flame such as oxygen-acetylene to melt and cut the steel pipe. The flame cutting speed is relatively fast and is suitable for cutting thick-walled steel pipes. However, the quality of the cutting surface after flame cutting is slightly worse, and there may be a certain heat affected zone, which requires subsequent processing, such as grinding. It is often used in some occasions where the accuracy of the cutting surface is not particularly high, such as temporary cutting at the installation site of some industrial pipelines.

Plasma cutting: cutting steel pipe by high temperature of plasma arc. This method has a fast cutting speed and can cut various steel pipes with complex shapes, and the quality of the cutting surface is better than flame cutting. For example, in the manufacture of auto parts, for some irregularly shaped steel pipe parts, plasma cutting can efficiently complete the cutting task, and can realize automatic cutting.

Bending

Cold bending: bending the steel pipe at room temperature. Through special pipe bending equipment, such as CNC pipe bending machine, the steel pipe is bent around the mold into the required shape. The cold bending process can accurately control the bending angle and radius, and is suitable for the bending of small-diameter steel pipes. For example, in furniture manufacturing, some steel pipe furniture frames need to be bent into various shapes, and cold bending processing can meet this high-precision bending demand.

Hot bending processing: For some steel pipes with larger wall thickness, larger diameter or harder material, cold bending may cause problems such as steel pipe cracking, and then hot bending processing is required. Hot bending is to bend the steel pipe after heating to a certain temperature. Heating can reduce the yield strength of the steel pipe and make it easier to bend. In the pipeline laying of the petrochemical industry, when some large-diameter pipelines need to bypass obstacles, hot bending processing can make the pipeline bend smoothly and ensure the continuity of the pipeline.

Welding processing

Butt welding: welding the ends of two steel pipes after butt welding is one of the most commonly used methods in steel pipe connection. In the welding process, it is necessary to ensure the quality of the welded joint, including the strength and sealing of the weld. For example, in the construction of long-distance oil pipelines, a large number of butt welding is used to connect steel pipes. By selecting appropriate welding processes (such as automatic submerged arc welding, manual arc welding, etc.) and welding materials, the strength and sealing of the pipeline are ensured to prevent oil Leakage.

Angle welding: mainly used for connection between steel pipes at a certain angle. In steel structure construction, the connection between steel pipe column and steel pipe beam may use corner welding, this welding method can make the steel pipe structure form a stable frame, and can adjust the angle according to the design requirements to meet the mechanical performance requirements of the building structure.

Surface treatment

Galvanizing treatment: A layer of zinc is plated on the surface of the steel pipe to effectively prevent the steel pipe from rusting. Methods of galvanizing are hot dip galvanizing and electro galvanizing. Hot galvanizing is to immerse the steel pipe in molten zinc to attach a layer of zinc to the surface of the steel pipe. Electrogalvanizing is through the way of electrolytic deposition of zinc on the surface of the steel pipe. The hot-dip galvanized layer is thicker and has better anti-corrosion performance. It is generally used in outdoor steel pipe structures, such as power towers, street lamp poles, etc.; the electro-galvanized layer is thinner and the surface is smoother. It is often used in some indoor steel pipe products with slightly lower appearance and anti-corrosion requirements.

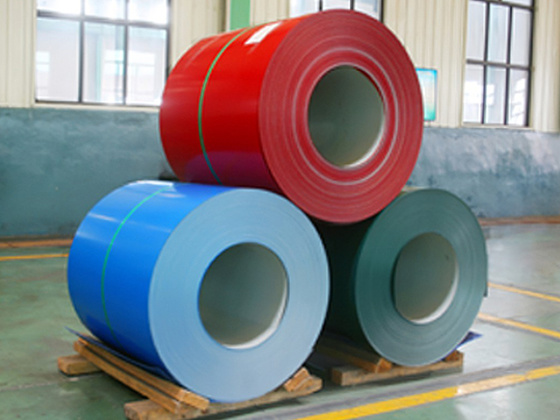

Painting treatment: Coating various paints on the surface of the steel pipe can not only play an anti-corrosion effect, but also play a decorative role. For example, in the construction of steel pipe scaffolding, coated with anti-rust paint can extend the service life of the steel pipe, while some colored paint can also play a role in identification, to facilitate construction management. There are spraying and brushing methods for painting. Spraying can make the paint more evenly distributed and more efficient.

Plastic spraying treatment: The plastic powder is attached to the surface of the steel pipe by electrostatic spraying, and then cured at high temperature to form a layer of plastic protective film. The steel pipe after spray treatment has good corrosion resistance, wear resistance and aesthetics. It is widely used in steel pipe products such as metal stents and fitness equipment for some home appliances.

Application areas

Construction industry

In the building structure, steel pipe deep processing products are used to build steel structure frame. The steel pipe after cutting, welding and surface treatment can be used as the main components of the building, such as columns and beams, and can also be used to make the keel of the building curtain wall. In terms of building decoration, such as stair handrails, railings, etc., the steel pipe after bending and surface treatment can meet the requirements of beauty and safety.

Automotive industry

Steel pipes are used in the exhaust system and frame structure of automobiles. Deep-processed steel pipes, such as high-precision cutting and special-shaped bent steel pipes, can meet the precise assembly requirements of auto parts. Moreover, auto parts also have higher requirements for the corrosion resistance and strength of steel pipes. Processing technologies such as surface treatment and welding can improve the applicability of steel pipes in automobiles.

petrochemical industry

Petroleum and chemical pipeline systems use a large number of steel pipes. Pipeline cutting, welding, bending and other processing technology to ensure that the pipeline can be smoothly laid in the complex chemical plant, connecting the various equipment. At the same time, the surface treatment can prevent the steel pipe from being corroded by the chemical medium and ensure the safety and stability of chemical production.

Furniture industry

Steel tube furniture is an important application field of steel tube deep processing. Through bending, cutting and surface treatment, steel pipes can be made into various furniture, such as tables and chairs, bed frames, etc. Furniture steel pipes usually require good appearance and suitable mechanical properties. The processing technology can make the steel pipes meet these requirements, and can be customized according to different design styles.

Hot Tags:

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!